Walk into any showroom and the first thing that determines whether a fabric convinces or fails is not a lab report — it’s the eye. A shade that doesn’t match across rolls, a subtle slub in a fine wool, or a seam slightly off balance is often enough to make a buyer reject an entire lot. In today’s textile industry, where speed and global supply chains dominate, these errors can carry staggering costs.

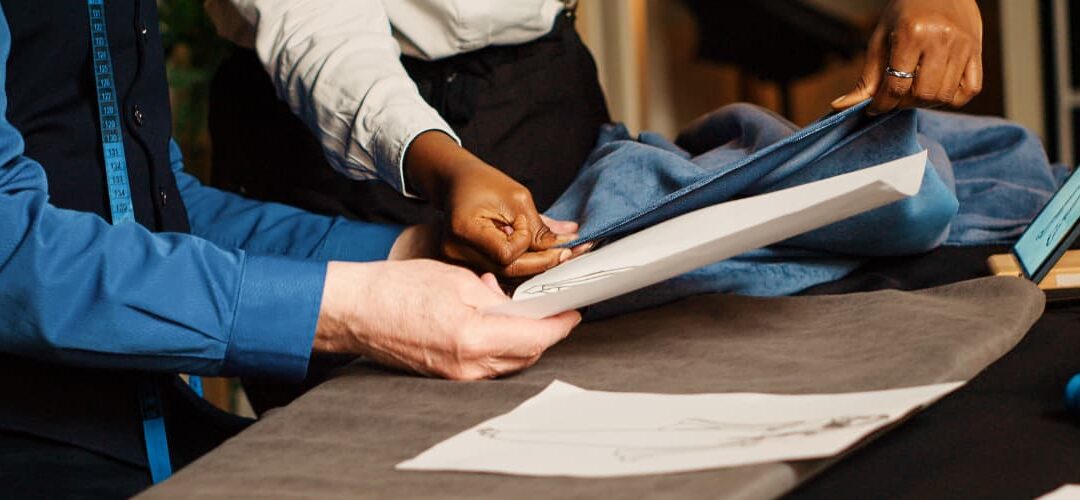

While chemical tests, performance trials, and laboratory analysis are indispensable, un'ispezione tessile remains the first and most decisive barrier against quality failures. At Mars Quality, we view visual inspection not as a routine checklist but as a disciplined blend of skill, methodology, and experience. It is where technical precision meets the human capacity to judge aesthetic and functional quality — a balance no machine has yet mastered fully.

2. Defining Visual Inspection in the Textile Industry

Visual inspection in textiles refers to the systematic evaluation of fabrics, garments, or accessories to ensure they conform to defined specifications. It covers more than just “looking” — it involves structured checks under standardized conditions to assess:

- Appearance (surface defects, weave integrity, uniformity).

- Color (shade, consistency, metamerism under different lights).

- Finishing (softness, drape, coatings, special treatments).

- Construction (seams, trims, alignment).

Unlike laboratory testing, which isolates properties such as tensile strength or chemical resistance, visual textile inspection captures the perceived quality as the end customer will see it. The two approaches complement each other, but only visual inspection can reliably detect aesthetic or surface-level flaws before shipment.

Here are some photos taken during actual textile inspections carried out by Mars Quality:

3. Core Techniques of Textile Visual Inspection

a. Lighting Conditions and Environment

Light defines what the inspector sees. Inspections conducted under uncontrolled conditions often miss subtle color deviations. Professionals therefore rely on standardized light sources:

- D65 daylight simulators for neutral assessment.

- Fluorescent and LED sources to check for metamerism.

- Color assessment booths with neutral gray surroundings to avoid visual bias.

b. Fabric Surface Examination

Inspectors examine fabric surfaces for weaving and knitting defects. Using pick glasses or magnifiers, they detect:

- Broken ends or picks.

- Floats, snags, or slubs.

- Oil stains, dirt marks, or holes.

Techniques differ between woven fabrics (warp/weft uniformity) and knits (loop structure, runs, distortion).

c. Color and Shade Evaluation

Shade consistency is critical in fashion and home textiles. Inspectors:

- Compare rolls or garments against approved lab dips or swatches.

- Test under multiple light sources to catch metamerism.

- Use gray scales to measure color change and staining.

Here are some photos taken during actual textile inspections carried out by Mars Quality:

Color Check

Color shading test

d. Pattern and Print Alignment

Whether stripes, plaids, or digital prints, alignment is inspected across rolls and garment panels. Poor registration or irregular repeats can make a design unusable.

e. Finishing and Hand Feel Assessment

Beyond visual checks, inspectors evaluate hand feel and finishing quality:

- Drape, softness, and uniformity of brushing or shearing.

- Consistency in coatings, laminations, or water-repellent finishes.

- Spotting issues like uneven embossing or streaks in dyed fabrics.

f. Garment-Specific Checks

In apparel, the scope expands to construction:

- Seam puckering, skipped stitches, or loose threads.

- Quality of trims (zippers, snaps, buttons).

- Symmetry of panels and correct placement of labels or appliqués.

4. Structured Inspection Frameworks in Textiles

The industry relies on standardized grading systems to quantify visual inspection results:

- 4-Point System: Assigns penalty points to defects by size and severity, widely used in fabric mills.

- 10-Point and Graniteville Systems: Legacy methods, still used in certain regions.

- AQL (Acceptable Quality Level): Statistical sampling applied to finished garments and accessories.

Mars Quality inspectors adapt these frameworks based on the client’s requirements, ensuring reports align with both buyer specifications and international standards.

5. Tools & Technologies Supporting Visual Inspection

While visual judgment is human, tools enhance accuracy:

- Pick counters and magnifiers for weave density checks.

- Shade cards and gray scales for color assessment.

- Digital defect scanners and automated shade-matching devices in advanced facilities.

Still, many defects — such as irregular hand feel or subtle shade imbalance — remain dependent on experienced human evaluation.

6. Common Defects Identified Through Visual Inspection

- Fabric defects: barre, bowing, skewness, uneven dyeing, stains.

- Color/print defects: shade variation, off-register prints, color bleeding.

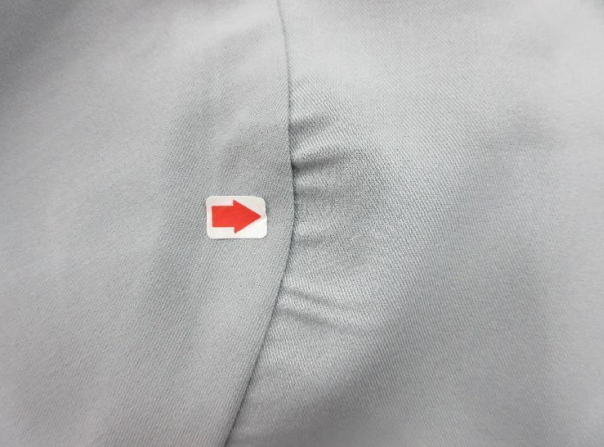

- Garment defects: uneven seams, misaligned trims, visible puckering.

Mars Quality’s inspections often reveal issues invisible at first glance but significant once products reach retail shelves. This ability to detect and document defects early saves buyers costly disputes and rejected shipments.

Here are some photos taken during actual textile inspections carried out by Mars Quality:

Stain

Pulled Yarn

Untrimmed Thread

Crinkle

Drawn Yard

7. Mars Quality’s Approach to Textile Visual Inspection

Mars Quality combines technical rigor with local knowledge. Our inspectors are trained across textile categories — from luxury fabrics in Italy to mass-market garments in China. Key elements of our approach include:

- Custom checklists adapted to each product type.

- Integration of AQL and fabric grading systems in practical field inspections.

- Multilingual reporting in English, French, Italian, and Spanish.

- Action-oriented reports that highlight problems and propose corrective steps.

8. Conclusion & Call to Action

In textiles, perceived value begins with what the eye sees. A product may pass every lab test, but if a shade is inconsistent or a seam looks flawed, quality in the customer’s mind is lost. Visual inspection remains the critical safeguard in every supply chain.

Mars Quality supports international brands, retailers, and sourcing offices with professional textile inspection services worldwide. Our structured, consultative approach ensures that every roll, garment, or accessory is evaluated with precision and expertise.

Contact Mars Quality today to strengthen your textile quality control program and secure your supply chain.