Product Inspection Services in China

Product Inspection Company in China – Mars Quality

Mars Quality provides impartial product inspection services in China for international buyers, retailers, and manufacturers. With local teams stationed at factories, packing houses, and production sites, we ensure that every shipment meets agreed specifications, compliance standards, and customer expectations.

Sourcing products from China can be complex: varying supplier practices, large production volumes, and multi-component shipments create opportunities for defects, mislabeling, or non-compliance. As a Quality Control Company in China, Mars Quality mitigates these risks by combining industry expertise, systematic inspection protocols, and actionable reporting.

Our inspectors are trained in technical quality control across industries, including textiles, electronics, automotive, food, and consumer goods. Every inspection provides not just a pass/fail evaluation but detailed insights to help improve supplier performance and safeguard supply chain integrity.

We provide detailed product inspection reports within 24 hours that offer clear insights into the quality of your products, helping you make informed decisions and maintain a competitive edge in the market.

Types of Product Inspection Services We Offer in China

Mars Quality offers a comprehensive suite of product inspection services in China, tailored to each stage of production and shipment. Our services are designed to catch defects early, ensure compliance, and protect your supply chain from costly errors.

Initial Production Inspection

-

Conducted at the start of production to verify raw materials, components, and initial samples.

-

Confirms alignment with design specifications, technical standards, and client requirements.

-

Helps prevent systemic issues from progressing further in production.

Pre-Shipment Inspection

-

Conducted when 80–100% of the order is completed and packed.

-

Focuses on product quality, packaging, labeling, and quantity accuracy.

-

Ensures that items meet agreed specifications before leaving the factory.

Sorting & Rework

Mars Quality also provides sorting services to help manage and rectify quality issues that may arise during production. Our inspectors meticulously sort through batches of products to identify and separate defective items from those that meet quality standards. This service is crucial for maintaining product consistency and ensuring that only top-quality products are delivered to your customers.

During Production Inspection

-

Performed during manufacturing to identify and correct issues early.

-

Reduces risk of large-scale defects and minimizes rework costs.

-

Common checks: material quality, component assembly, in-process functionality.

Container Loading Check

-

Ensures goods are correctly packed and secured for shipment.

-

Verifies palletization, labeling, carton integrity, and overall compliance with shipping standards.

-

Minimizes damage and delays during transit.

Need Product Inspection Services in China?

Our Product Inspection Service Approach in China

At Mars Quality, we follow a structured, industry-focused approach to ensure every product inspection service in China delivers actionable results and mitigates supply chain risks. Our methodology balances technical rigor with practical recommendations, providing buyers not just a pass/fail outcome but insights to improve supplier performance.

1. Planning & Sampling

Before arriving on-site, our inspectors review product specifications, client requirements, and production details. A sampling plan is created based on international standards and order size to ensure that inspections are statistically representative and aligned with your risk tolerance.

2. On-Site Visual & Functional Checks

Inspections are conducted directly at factories, production lines, or packing facilities. Our inspectors assess:

- Product dimensions and tolerances

- Surface quality, finishes, and workmanship

- Assembly accuracy and functional performance

- Packaging integrity and labeling accuracy

3. Testing & Verification

Depending on the product type, basic functional or quality tests are performed. Examples include:

- Electrical function tests for electronics

- Load and stability tests for furniture or industrial equipment

- Colorfastness and fabric strength for textiles

- Weight, hygiene, and packaging verification for food products

4. Reporting & Recommendations

Every inspection concludes with a detailed report including:

- Photographs of inspected items

Pass/fail assessments for each criterion - Observations and corrective action suggestions

- Summary of compliance with client requirements and standards

Looking for a Product Inspection Company?

Industries & Products We Inspect in China

Mars Quality provides comprehensive product inspection services in China across a wide range of industries and product categories. Our inspectors are trained to evaluate both finished products and components, ensuring quality, compliance, and functionality at every stage.

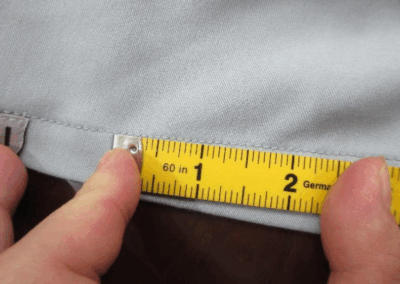

Textiles & Apparel

- Clothing, footwear, home textiles, technical fabrics

- Checks: fabric quality, stitching, colorfastness, labeling compliance, size accuracy

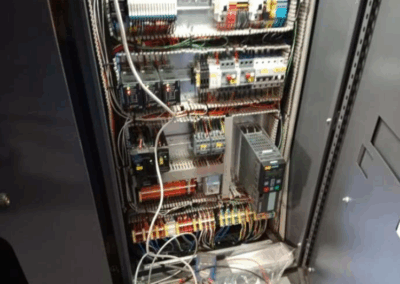

Electronics & Electricals

- Consumer electronics, batteries, cables, small appliances

- Checks: functional performance, component integrity, regulatory compliance (CE/FCC), packaging

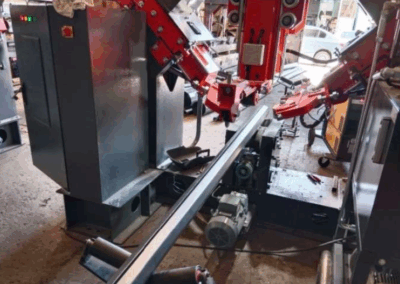

Industrial Equipment & Tools

- Machinery, hand tools, power tools, metal components

- Checks: material quality, structural integrity, performance, safety compliance

Furniture & Home Goods

- Indoor/outdoor furniture, décor, home textiles

- Checks: material quality, structural stability, assembly, finishing, safety standards

Additional Product Categories

- Medical Devices & Equipment: Basic functionality, labeling, packaging, regulatory compliance

- Packaging & Printing Materials: Box quality, printing clarity, logo placement, finishing defects

- Luxury Goods & Accessories: Leather goods, watches, bags, jewelry – checking finishing, material quality, and packaging integrity

Food & FMCG Products

- Packaged foods, frozen products, beverages, spices, herbs, confectionery

- Checks: hygiene, packaging integrity, labeling compliance, weight/quantity, storage conditions

Automotive Components

- Spare parts, electrical modules, suspension components, accessories

- Checks: dimensional accuracy, material grade, surface finish, functional testing, OEM compliance

Home Appliances & Consumer Goods

- Small appliances, cookware, home gadgets

- Checks: functionality, safety, packaging, labeling, warranty documentation

Toys & Children’s Products

- Plastic toys, plush toys, educational kits, baby products

- Checks: safety, durability, labeling, age-appropriate compliance, mechanical tests

How to Organize a Product Inspection in China with Mars Quality

At Mars Quality, every product inspection in China follows a structured, transparent process to ensure accuracy, consistency, and actionable results. Our step-by-step methodology allows buyers to have full confidence in their supply chain.

1. Client Consultation & Specification Review

- Discuss product specifications, industry requirements, and quality expectations.

- Review previous inspection reports, supplier history, and any known risk areas.

- Define inspection objectives and scope tailored to each client and product.

2. Inspection Planning & Scheduling

- Assign a local inspector with industry-specific expertise.

- Determine sample size and inspection type based on order volume and product complexity.

- Coordinate timing to align with production schedules or pre-shipment readiness.

3. On-Site Inspection Execution

- Inspect products at the factory, production line, or packing facility.

- Conduct visual, functional, and technical checks according to the inspection plan.

- Document findings with photographs, measurements, and detailed observations.

4. Comprehensive Report & Follow-Up

- Deliver an inspection report that includes:

- Pass/fail results for each criterion

- Photos illustrating defects or compliance issues

- Recommendations for corrective actions

- Provide guidance to suppliers to rectify issues before shipment.

5. Optional Supplier Performance Feedback

- Analyze recurring defects or patterns across multiple inspections.

- Offer suggestions to improve production processes, supplier reliability, and overall quality.

Why Choose Mars Quality for Product Inspections in China

Choosing Mars Quality for product inspection services in China means partnering with a team that combines local expertise, technical precision, and actionable insights. Our approach goes beyond checking boxes; we provide clarity, transparency, and solutions that protect your supply chain. By working with us, buyers gain confidence, full visibility, and control over their supply chain, ensuring products meet the highest quality standards before leaving China.

Local Experts Across China

Inspectors are stationed in key manufacturing regions, including Guangdong, Zhejiang, Jiangsu, and Shanghai. Multilingual teams ensure smooth communication with factories and accurate reporting for international clients.

Industry-Specific Expertise

Inspectors trained in textiles, electronics, automotive, food, industrial equipment, and consumer goods. Ability to identify subtle defects or compliance issues that may go unnoticed by general inspectors.

Actionable Reporting

Comprehensive inspection reports with high-quality photographs, detailed observations, and corrective recommendations. Clear pass/fail criteria linked to client specifications and industry standards.

Risk Mitigation & Supplier Improvement

Early detection of defects prevents costly rework and shipment delays. Insights shared with suppliers to improve processes, reduce errors, and strengthen long-term reliability.

Flexibility & Tailored Solutions

Custom inspection plans for high-risk shipments, multi-component products, or complex supply chains. Scalable services for both small and large-volume orders.

Related Content

Explore more insights and resources on product and finished goods inspection services in China:

FAQ – Product Inspection Services in China

What is included in a pre-shipment product inspection service in China?

A pre-shipment inspection (PSI) evaluates finished goods for compliance with specifications, quantity, packaging, labeling, and overall quality before shipment.

How do you select inspection samples?

Sample sizes are determined based on order quantity, product type, and risk level, following international standards.

How long does a typical product inspection in China take?

Most inspections are completed within 1–3 days; larger or multi-factory projects may require extended schedules.

Can Mars Quality handle multiple factories in different cities?

Yes. Inspectors are located in all major manufacturing regions across China.

Do you inspect both finished products and components?

Yes. We inspect raw materials, components, in-process goods, and finished products.

What languages are inspection reports provided in?

Reports are available in English, with optional translations in French, Italian, and Spanish.

How do you ensure impartiality in product inspection services in China?

Mars Quality is an independent third-party provider. Inspectors report directly to the client.

What standards do you follow during product inspections?

Mars Quality follows international standards such as ISO 2859 for sampling, AQL (Acceptable Quality Level) for defect assessment, and product-specific standards (CE, FCC, FDA, etc.) to ensure global compliance.

Can you inspect in-process production before final assembly?

Yes. During Production Inspection (DUPRO) allows early detection of defects, ensuring that quality issues are corrected before final assembly or packaging.

Get in touch with our experts today