Food Inspection Services – Global Food Quality Inspection Company

Mars Quality – International Food Inspection Service Company

Mars Quality specializes in providing technical and independent food inspection services for companies operating in the agricultural, food manufacturing, and food export industries across the globe. We cover 100 countries—including Egypt, India, Philippines, Thailand, China, Korea, Indonesia, Malaysia, Turkey, Greece, Romania, Bulgaria, Spain, Italy, France, Belgium, Poland, Norway, Chile —we support exporters, importers, retailers, and brands in ensuring consistent quality and compliance throughout their food supply chains.

Our role is clear: to help you secure the quality, safety, and compliance of your food shipments—whether they are fresh fruits, vegetables, spices, herbs, meat, seafood, processed products, or beverages. Through detailed inspections performed by experienced professionals, Mars Quality helps prevent costly rejections, brand damage, and regulatory non-conformances.

Our food inspection company combines commodity-specific technical knowledge with real-world operational expertise. Every inspection is adapted to the product’s nature, the destination market’s requirements, and the buyer’s expectations, providing you with true commercial protection.

Our Food Inspection Services

Mars Quality supports the food sector from harvest to final shipment. Our food inspection services help businesses catch defects early, maintain regulatory compliance, and safeguard consumer trust. Each type of inspection focuses on specific risks relevant to the production stage and product sensitivity.

Every inspection report includes photographic documentation, data summaries, inspector commentary, and clear recommendations (Accept, Rework, Reject).

We provide a full suite of inspections customized to food products and export conditions:

Initial Production Inspection

An Initial Production Inspection verifies the very first units produced or packed:

- Reviewing harvest practices and maturity criteria (for fruits, vegetables, herbs)

- Checking initial product batches for conformity in size, color, and defects

- Confirming correct use of packaging and labeling materials

- Assessing basic hygiene and handling practices at the production site

Pre-Shipment Inspection (PSI)

The Pre-Shipment inspection before dispatch:

- Full visual and sensory evaluation of packed goods

- Statistical AQL sampling adapted to food commodities

- Verifying packaging integrity, labeling accuracy, and correct documentation

- Temperature verification for refrigerated or frozen items

During Production Inspection (DUPRO)

DUPRO Inspection monitors ongoing production or packing runs:

- Verifying size uniformity, weight conformity, and defect rates

- Checking the cleanliness and condition of work areas

- Monitoring cold chain conditions for perishable goods

- Spot-checking labeling and packaging midway through production

Container Loading Check

Container loading is a critical risk point. It ensures:

- Cleanliness of the container (no contaminants, odors, or pests)

- Correct palletization and load securing

- Verification of reefer settings (for chilled/frozen goods)

- Proper documentation, sealing, and final container integrity

Supporting a Wide Range of Clients – From Exporters to Retailers

Each client benefits from a customized approach designed around their products, markets, and operational priorities. Mars Quality’s food inspection services cater to a diverse portfolio of clients:

Exporters and Growers

We help producers and growers ensure that their harvests and packed shipments meet buyer standards and phytosanitary regulations.

Processors and Manufacturers

We assist food manufacturers in maintaining consistency across production batches and preparing goods for export markets.

Importers and Retailers

We serve as the inspection partner for importers and retail chains, verifying that incoming shipments meet agreed specifications and national safety standards.

Small and Medium-Sized Enterprises (SMEs)

We offer flexible, scalable inspection solutions for growing companies needing cost-effective quality assurance.

What We Inspect – A Broad Range of Food Products

Mars Quality has extensive experience across all major food sectors:

Fresh Produce

-

- Fruits: Mangoes, avocados, apples, citrus fruits (oranges, lemons, mandarins), bananas, grapes, berries (strawberries, blueberries, raspberries), kiwis, pears, pineapples, pomegranates, melons, plums.

- Vegetables: Tomatoes, leafy greens (spinach, lettuce, arugula), bell peppers (red, yellow, green), carrots, cucumbers, broccoli, cauliflower, onions, potatoes, sweet potatoes, zucchini, green beans, asparagus, eggplants.

- Herbs: Basil, mint, coriander, oregano, parsley, rosemary, dill, thyme, chives, sage, tarragon.

- Fruits: Mangoes, avocados, apples, citrus fruits (oranges, lemons, mandarins), bananas, grapes, berries (strawberries, blueberries, raspberries), kiwis, pears, pineapples, pomegranates, melons, plums.

Spices and Dried Products

-

- Spices: Black pepper, white pepper, cumin, paprika, cardamom, turmeric, cinnamon, cloves, nutmeg, coriander seeds, fennel seeds, star anise, saffron, chili powder.

- Dried Herbs: Oregano, basil, thyme, rosemary, sage, marjoram, mint leaves, bay leaves.

- Dry Food Ingredients:

- Flour: Wheat flour, rice flour, corn flour, chickpea flour

- Sugar: White sugar, brown sugar, raw sugar, powdered sugar

- Grains and Pulses: Rice (white, basmati, jasmine), wheat, quinoa, lentils (red, green), chickpeas, mung beans, kidney beans

- Nuts and Seeds: Almonds, cashews, walnuts, pistachios, sesame seeds, sunflower seeds, chia seeds, flaxseeds

Meat, Seafood, and Fish

-

- Meat: Beef (chilled, frozen), lamb, poultry (chicken, duck, turkey), veal.

- Seafood: Shrimp (black tiger, white shrimp), tuna (yellowfin, skipjack), salmon (wild, farmed), whitefish (cod, haddock, tilapia), shellfish (scallops, mussels, oysters), squid, octopus, lobster.

- Meat: Beef (chilled, frozen), lamb, poultry (chicken, duck, turkey), veal.

Processed Foods and Beverages

-

- Processed Foods: Canned fruits (pineapple, peaches, lychees), canned vegetables (corn, peas, beans), frozen vegetables (broccoli, spinach, mixed vegetables), frozen fruits (berries, mango chunks), jams and preserves, ready meals (frozen lasagna, rice dishes, pasta meals), dairy-based desserts, sauces and condiments (tomato sauce, curry pastes).

- Beverages: Fruit juices (orange, apple, mango, grape), bottled teas (green tea, black tea, herbal blends), carbonated drinks (cola, flavored sodas), energy drinks, flavored water, alcoholic beverages (wine, beer, spirits like vodka, rum, whiskey).

- Processed Foods: Canned fruits (pineapple, peaches, lychees), canned vegetables (corn, peas, beans), frozen vegetables (broccoli, spinach, mixed vegetables), frozen fruits (berries, mango chunks), jams and preserves, ready meals (frozen lasagna, rice dishes, pasta meals), dairy-based desserts, sauces and condiments (tomato sauce, curry pastes).

Our Food Inspectors – Experienced and Technically Skilled

Mars Quality’s team of inspectors are more than field agents—they are trained food quality experts.

Inspector Qualifications

- Backgrounds in agricultural sciences, food technology, or related fields

- In-depth commodity expertise (fresh produce, seafood, spices, meat, processed foods)

- Knowledge of post-harvest handling and cold chain logistics

- Proficiency in sensory evaluation methods

- Practical application of AQL (Acceptable Quality Level) sampling adapted for perishables

- Awareness of market-specific regulatory frameworks (FDA, EU Regulation 178/2002, Codex Alimentarius)

Key Competencies

- Detecting critical, major, and minor defects based on commodity-specific criteria

- Conducting real-time temperature measurements with calibrated digital thermometers

- Identifying potential contamination risks during production or packing

- Verifying labeling for regulatory compliance in destination markets

Food Inspection Services: List of Verifications, Testing, and Controls

Mars Quality inspections are structured around a comprehensive Food Inspection Checklist, adapted to each product category and shipment type.

Our standard inspection points include:

1. Food Product Quality and Safety

-

Visual defects: bruises, blemishes, mold, mechanical damage

-

Size, weight, and grading checks

-

Freshness indicators: firmness, color, aroma

-

Core temperature measurements for chilled and frozen goods

-

Shelf-life validation: expiry date versus product condition

-

Detection of foreign objects (e.g., stones in spices, bones in fish fillets)

Image captured during a pepper pre-shipment inspection conducted by Mars Quality. >>

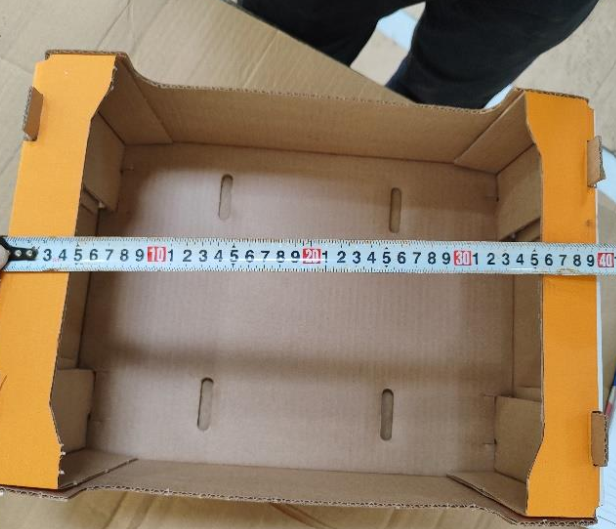

2. Food Packaging and Labeling Control

-

Primary packaging integrity (vacuum packs, cans, trays, etc.)

-

Secondary packaging strength and compliance (cartons, pallets)

-

Label checks:

-

Correct product name

-

Net weight and quantity

-

Ingredients and allergen declarations

-

Best-before and packing dates

-

Country of origin

-

Regulatory compliance (FDA, EFSA, SFDA, depending on market)

-

Image captured during a vegetables pre-shipment inspection conducted by Mars Quality. >>

3. Loading Verification

-

Palletization method validation

-

Container cleanliness inspection

-

Reefer container settings (if applicable)

-

Cargo securing and load stability checks

-

Final sealing verification and documentation

Image captured during a container loading inspection conducted by Mars Quality. >>

Food Inspection Services in Egypt

Our Complete Range of Food Quality Control Solutions

Why Choose Mars Quality for Food Inspection Services?

Partnering with Mars Quality offers measurable advantages:

-

Global Coverage: solutions in 100 countries

-

Technical Expertise: Experienced quality inspectors

-

Detailed and Rapid Reporting: Comprehensive inspection reports delivered within 24-48 hours

-

Flexible Services: Inspections customized to your operational realities

Where Do We Offer

Food Inspection Services

Our global presence allows us to support businesses with operations in multiple regions, offering consistent sorting solutions across different markets.

Mars Quality provides food quality checks in 100 countries including:

Albania, Austria, Belgium, Bulgaria, Croatia, Cyprus, Czechia, Denmark, Estonia, Finland, France, Germany, Georgia, Hungary, Italy, Lithuania, Romania, Netherlands, Norway, Portugal, Poland, Serbia, Slovenia, Slovakia, Spain, Sweden, Switzerland, United Kingdom, etc.

Argentina, Perú, Colombia, Brazil, Mexico, USA, Canada, etc.

Vietnam, China, Thailand, Cambodia, Taiwan, Bangladesh, India, Sri Lanka, Indonesia, Malaysia, Pakistan, Bangladesh, Nepal, Singapore, Hong Kong, etc.

Morocco, Algeria, Tunisia, Egypt, South Africa, etc.

Jordan, Turkey, Lebanon, Saudi Arabia, UAE, Oman, etc.

You need a trusted partner who understands your business

Mars Quality has the industry knowledge and resources to help you ensure quality and reduce risks.

Get in touch with our experts today

Related Solutions

Quality Inspections

Mars Quality’s professionals possess deep knowledge in delivering inspections of a wide range of complexity. We ensure product quality, by verifying compliance with the technical documents or product specifications shared by the client.

Factory Audits

We offer factory and supplier audit services to help you in your continuous improvement process. Our auditors verify supplier reliability, qualify new partners, prepare for certifications, and improve quality performance.